Vac Meter

2, discrete solid state. 2015.

The front panel, using retired 1980s obsolete university

gear.

Two more pictures at bottom of page.

In 2015 I wanted to improve the RF performance of my AM kitchen

radio so I

needed a Vac meter with wider bandwidth than the 2013 meter which gave

1.5Hz to 300kHz.

The aluminium case, meter, 3 pole 12 position rotary wafer were

found in

excellent condition within some old 1980 test gear rescued from

a rubbish bin

at ANU.

Contents of this page:-

Sheets 1 to 8 are schematics of my 2015 Vac meter giving 12 Vac

ranges for

0.5Hz to 5MHz :-

0.0Vrms to 1.0mV, 3.2mV, 10mV, 32mV, 100mV, 0.32V,

1.00V, 3.2V, 10.0V, 32V, 100V, 320V.

SHEET 1 :- Basic block diagram of whole unit.

SHEET 2 :- Rotary wafer switch Sw2A,B,C.

SHEET 3 :- Amp 1, gain = x10.00, +20dB.

SHEET 4 :- Amp 2, gain = x10.00, +20dB.

SHEET 5 :- Emitter follower buffers for CRO, F meter,

etc.

SHEET 6 :- Amp 3, gain = 1.0, +/- 0.0dB, meter driver.

SHEET 6A :- Amp 3 basic circuit + explanations of GNFB +

rectifiers.

Meter dial :- Image for customized analog meter dial to

reduce errors.

SHEET 7 :- Power supply, +/-15Vdc regulated.

Fig 1 :- Passive 1:1 or 10:1 R divider probe for CRO or

Vac meter.

Fig 2 :- Passive 10:1 capacitance divider probe for CRO

or Vac meter.

Fig 3 :- Active probe for CRO or Vac meter.

SHEET 9 :- Switched R divider for Vac range

calibration.

SHEET 9A :- Three useful attenuator switches for

calibration.

SHEET 8 :- Band-pass filtering for reducing noise.

SHEET 1 BLOCK DIAGRAM for 2015.

SHEET 1 is the overall picture of main element layout.

Many R are not numbered and 3 amp schematics have been reduced

to symbols.

The bypassing of Vdc rails to 0V and chassis case floor and

including LC filters

prevents RF instability.

There are three cascaded amplifiers with a huge

total amount of open loop

gain exceeding 100,000. Each amp has local or GNFB, and is

isolated to prevent

any oscillations. The +/- Vdc rails are well grounded to a very

low Z common path

of aluminium floor of the box. I used many 2uF polyester caps

rated for 250V and in

white plastic boxes. Xc 2uF = 0.08r at 1MHz. L3 to L6 = 40uH

chokes offer low R

between amp rails to maintain regulated +/-15Vdc. The 40uH + 2uF

form filter

networks to ensure any Vac above 10kHz at +/-Vdc rails cannot

find its way to

the next amp to cause oscillations. Each choke has 5 turns of

0.5mm Cu

insulated wire taken from Cat-5 cable and wound through 2mm bore

of ferrite

tube 20mm long, to make a toroid choke.

Protection against excessive Vac applied is shown after

Sheet-2 Amp1 and

Sheet-3 Amp2 schematics below.

Manual Vac range selection is easy for 12 Vac ranges from

1mVac to 320Vac.

After turn on, the unit takes 12 seconds for Vdc rails to fully

stabilize. I always

try to select a higher Vac range than the Vac I think may be

present.

Measuring above 320Vrms could be a problem if you don't

know the peak

Vac with a non sine wave. Most Vac in audio amps are sine waves,

square

waves, or triangular, but pulse waves and noise Vac may exceed

1,000V easily.

To measure Vac between 100V and 1,000V requires a resistance

divider rated

for Vac and Vdc peak levels. Tube amps create peak Vac + Vdc

above 3,000V.

A resistance divider shown on page for 2013 meter will

withstand 4,000Vdc for

5 minutes.

If the meter reads below 0.1 x full swing, better accuracy is

gained by switching

to a lower Vac range which will swing the needle higher for easy

accurate reading.

If the meter reads full scale, switch up to higher Vac ranges

until the meter settles

above 0.1 x full swing.

The Vac range labels tell you which dial to read, and practice

makes perfect !

SHEET 2 Input switching for Vac meter, 2015.

The Vac ranges are approximately 10dB apart. There are three

scales on the

dial plate of a 100mm wide analog meter. (more below).

For non standard R values, you MUST use only 1% metal

film in series or

parallel to get correct R within 1% or you get errors exceeding

1%.

Every R value shown allows for all combined loading by other R

around it

during use.

Trim caps C2 to C8 could be high V rated with adjust

screws for C = 3pF to 8pF.

I used turns of insulated wire from Cat-5 cable wound around 1mm

solid copper

poles 15mm long soldered to contacts of switch. Turns of wire

are adjusted for

flat sine wave response to 6MHz.

Cin of the meter is determined largely by the rotary

wafer switch with

unavoidable C < 20pF.

SHEET 3. Amp 1, gain x 10.

Protection for Amp-1. Accidental HV input damage

is limited by UF1004

clamping diodes d1-d6 UF4007 across Q1 gate to source, and from

source to 0V.

Amp 1 is used for V ranges 0 - 100mV. The max gate V swing = +/-

2.1Vpk.

If 500V is applied to V ranges 1-5, it is applied across R3

470r, 1/4W, current

exceeds 1A so R3 rapidly burns open. R3 needs only 23mA for

1/4W. A 50mA

fuse could be fitted to limit heat in R3 to 1.2W, but it would

still fuse open after

some time. The fuse and holder must be placed for easy

replacement and not

increase Cin.

SHEET 4. AMP 2, 2015.

Amp-2 input has Q1 source follower input buffer

with Rin = 2M2 and R3 + C1,

C2 form LF pole 0.09Hz. The 2M2 does not cause significant

loading of 1k0

network around Sw2C positions 1-5, or for SW2C positions 6 -12.

But R10 on

Sheet 2 needs to be trimmed carefully to get correct Vac

division.

Q1 2SK369 source has CCS dc feed from Q2 PN100 for high

open loop gain.

The Q1 follower isolates the input of following gain amp with Q3

to Q8, preventing

instability. R5 200r is prevents oscillations above 10MHz. Amp

Bandwidth is from

0.25Hz to 6MHz.

Protection for Amp-2.

When using the Vac ranges 1-5, Amp-2 is fed by Vac from output

of Amp-1 via

switch Sw2C and its resistance divider.

The highest normal Vac level into Amp-2 = 10mVac. But during

turn on/off, and

during gross overload of Amp-1, maximum possible Amp-2 input is

about +/- 7Vpk.

Therefore the high Vpk swing at Amp-2 input is limited to +/-

2Vpk by UF4007

diodes arranged for least increase of input C.

For Vac ranges 6-12, Amp-1 is not used. DUT input

is fed from outputs SW2C

R dividers to Amp 2 Q1 gate. The dividers all have 3M0 plus

smaller R, with the

largest small R = 98k, for V range 0 - 0.32Vac, position 6c. If

3,000V is accidentally

applied to input, maximum Vac output possibly applied from SW2C

at position

6c = 100Vac, but this is limited to +/-2Vpk by UF4007 around Q1

gate and

source to 0V. Maximum Iac in 3M0 with 3,000V applied = 1.0mA, so

heat in

3M0 = 3W, and with 2 x 1M5 in series each 0.5W rated, the R will

only fuse

if the high Vac is maintained for some time, which is very

unlikely.

Use of 3 x 1M0 each 1W would be better, but then I'd have more

clutter in a

small space.

Q1 source drives Q3+5 bases which are non-inverting input

to the gain amp.

The Q3+Q5 are in two parallel differential amps (LTP) with PNP

and NPN

bjts to give complementary action and best HF response.

I have idle Idc = 5.6mA in Q3,4,5,6 for high gm and high gain.

Differential gain is > 50 with collector loads of less than

2k2. Q7+Q8 have higher

gain in a complementary pair in common emitter mode.

Amp 2 open loop gain > 12,000 at 500Hz, but reduced to

just 10.00 with

62dB GNFB. Q7+Q8 collector outputs are loaded by NFB network

R21+R21.

The bottom of R21 is connected to 0V via C8+C9 each 8,200uF in

series.

These are 10Vdc rated electrolytics which each need 7.5Vdc by

divider with

R16+R16, each 10k0. So the effective C from R21 to 0V = 4,100uF,

and the

R22 300r + 4,100uF set an LF amp pole = 0.13Hz. The arrangement

gives

excellent Vdc stability.

To prevent inevitable RF oscillations with

"uncompensated" high gain amps,

the open loop gain is reduced with C7 trim-cap 9-35p in series

with VR1 1k0.

With VR1+C7correctly adjusted, there is no sign of oscillation

over 6MHz.

Amp 2 Q7+Q8 collector output is isolated from other

stages with 100r to inputs

of monitoring buffers on Sheet 5 and to Amp-3 input on Sheet 6.

The following amp stages have some shunt C which are likely to

cause RF

oscillations. Series R between 100r and 220r are used at input

or output to

prevent RF oscillations.

THD and noise is negligible.

SHEET 5..Emitter follower buffers. 2015.

Here are two simple emitter followers directly connected to

output of Amp 2.

These allow 2 external devices to be connected to the Vac meter

such as

Frequency meter, CRO, or alternative Vac meter. Such devices

cannot affect

the working of Amps1,2,3.

Protection. I have FR3004 diodes after output caps C1-4

to +/-15Vdc rails.

Q1+Q2 can only be fused with accidental application of HV to the

output

terminals. Excessive Iac or Idc current in R4 or R7 from an

external HV source

will fuse them open.

HF F2 > 5MHz, and F1 is determined by C1+R5, 5uF + 330k and

loading of

a CRO or other Vac meter etc in parallel.

If a CRO Rin = 1M0, R = 240k and -3dB F1 pole = 0.13Hz.

SHEET 6 Meter Amp 3.

Amp 3 is almost identical to amp 2 but without unnecessary input

emitter

follower stage because the previous Amp 2 has low output

resistance < 150r.

Amp 3 operation is DIFFICULT to understand.

SHEET 6A. Basic action in Amp 3.

Amp-3 on SHEET 6A is drawn here more simply with triangle symbol

used for

amplifier and the two + / - input ports have Rin approx 50k, and

the output at

Vo is a collector current source. R&C numbers on 6A are same

as for SHEET 6

Amp-3 schematic.

The metering function depends on a basic principle :-

Idc flow from charged C in a full wave rectifier circuit = 0.707

x Ia rms flow in

Vrms source.

Alternating current at output of Amp-3 is applied to a diode

bridge after to

produce dc flow in the meter coil R // VR3+R17. The Vac flow in

the meter R is

reduced to negligible levels with shunt C18+C19 so only DC is

applied to the meter.

The action is much like a full wave PSU rectifier where an AC

source charges

a C after a diode bridge, and the resulting Vdc without ripple

voltage is applied

to an R load. The C18 value must high at 470uF ripple Vac at low

F is very low,

and to prevent meter needle wobble exceeding + / - 10% at 0.5Hz.

There is negligible meter wobble at 5Hz. Amp-3 output Iac flows

through NFB

network which includes R15, diode bridge with 1N5711, C18+19 and

R16.

For meter full swing, Vac across R16 680r = 100mVrms, so Iac =

0.14706mArms.

Idc in VR3+R17 // meter R = 0.14706mAdc.

Meter R = 1k0 and the adjusted total of VR3+R17 = 3.125k, so

total R load for

DC flow = 680r, hence Idc = 0.1Vdc / 680r = 0.14706mAdc. The

adjustment of

VR3 is fairly sensitive and you could use 1k0 trim pot + 2k7.

Amp-3 output is from Q5+Q6 collectors which are a virtual

current source with

Ro > 50k0. If the output produces + 0.147 mA pk for 0.1Vrms

at R16, and if open

loop gain = 10,000, then Vac difference between input ports =

10uV.

The transconductance of the amp is transformed by voltage gain

to be about 14A / V.

The Vac across R16 680r is made linear to input Vac by GNFB,

80dB max at 500Hz.

Thus current flow from Q5+6 is controlled accurately by GNFB.

Vac across R16 is

almost identical in wave shape to the input Vac at Amp-3 input.

The GNFB Vac at R16 contains THD in current flow with diodes and

rectifier.

This is amplified to prevent its creation, so that Amp-3 output

voltage is varied

to do whatever is needed to reduce THD at R16. This ensures the

Idc flow to

meter is linearly proportional to the Iac rms flow in R16, and

that the Vdc applied

to meter tells us the True Vrms value for any Vac input wave

form.

With sine waves at both input ports, the wave at collector

output appears like a

square wave with verticals = +/- 0.5V approx, top and and bottom

horizontals

are curved up and down.

The relationship between Vrms, Voltage Root mean square and Vdc

is explained

further at Fig 5, 1/2 way down page at 2013 Vac Meter.

Root mean square, rms,

is also defined better than I could at

https://en.wikipedia.org/wiki/Root_mean_square

Basic units need to be understood.

The Watt is a current flow = 1 Coulomb per second

= 6.2415 x (10 to power of 18 ) electrons, which is called 1.0

Joule.

This is the number of electrons in a 1 Farad capacitor charged

to 1 Volt.

This is the number of excess electrons above what would exist if

there is no

measurable Vdc across the capacitor.

Where you have 1 Volt applied to 1 Ohm, I = V / R = 1

Amp.

For 1 second, the work done is 1 Joule, or 1Coulomb per second.

So where you have 1 Amp of current flowing,

there are 6.2415 x 10 to power of 18 electrons flowing per

second.

Electrical power is done at a rate per second measured in

Watts :-

Power, Watts = ( V x I ), or ( V squared / R ) or ( I squared

x R ).

The power generates heat in a resistance, causes motion in an

electric motor,

removes heat in a refrigerator, creates sound in air or water.

Electricity bills have power units in Kilowatt Hours,

kWh.

My typical winter bill is 16kWh per day. I day = 24hrs, so each

hour the average

power = 16 / 24 = 666.6Watt-hours. It means 666.6W is average

drawn each hour.

Current = P / V = 666.6 / 240V = 2.78 Amps rms. 667Watts is

about equal to

1/3 a 2kW rated room heater, equal to 0.89Horse power, and about

30 times the

average power I generate within myself when not doing much, and

is about 5

times the power I generate when riding a bicycle 30km across

town to have coffee.

Modern civilization is an extremely energy hungry beast compared

to 1717 before

the industrial revolution where the vast majority of all ppl

were poor, and survived

by producing 591Watt-hours each day.

A sine wave alternating flow of current must have peak +/- Vac =

1.414V to

provide the same heating power in R as 1.0Vdc. The sine wave V

and I can

be expressed in terms of Root mean square which equates the Vac

and Iac

as equivalent to Vdc and Idc which will generate the same power

in an R,

called RL, Resistance Load.

The peak Vac and peak Iac may vary greatly for any electric flow

wave form,

but whatever these V & I values may be, the Vrms and Irms

can be measured

using the meter I describe here, and in all meters giving "True

Vrms" so the

question in your mind, "What is electricity?" need not ruin your

day.

It can be proven mathematically that some simple Vac waves of

+/-1V peak at

any constant frequency have Vrms values according to a simple

table :-

Square wave, 1.0Vrms = Peak Vac / 1,

Sine wave, 0.707Vrms = Peak Vac / sq.rt 2,

Triangular wave, 0.577Vrms = Peak Vac / sq.rt 3.

Vac wave-forms we measure have have very different shapes and

may be

usually measured in Vpk, Vpk-pk, or Vrms.

Pink noise signals used for testing speakers sounds like a

rumbly big waterfall,

and on the CRO it looks like a very blurry display because of

the constant

randomly varying amplitude, frequency and phase. If we measure

pink noise

Vac as Vrms, the meter may show slow Vrms changes due to very

low F within

the noise causing meter needle to wobble.

The Vrms voltage measurement of Vac will be found to generate

the same

heating in a load R as would the same applied DC Vac or Iac

waves may

be a series of regularly repeating pulses of varying lengths of

time, and may

be seen as a stationary wave on a CRO because of the repeating

triggering

time of the CRO. The peak value of Vac or Iac change could be

many times

the Vrms value.

So peak Vac measurements alone do not tell us how much

continuous power

that wave will deliver to a load, only the maximum peak current

and power.

Engineers find it useful know the Vpk and Ipk as well as the

True Vrms and Irms.

If we can see Vpk for a wave on CRO, we can calculate the peak

Iac for a given

load R. We can estimate average Iac from the wave shape and its

duration as a

fraction of total time for 1 wave, and work out the power

liberated in the R load

where that Iac exists.

The Iac flow in a transformer winding feeding a diode rectifier

and can be viewed

on a dual trace CRO using both channels in differential mode

across a 10r0 in

series with winding end and input to diodes before the reservoir

C, if one is used.

Amp-3 open loop gain = 12,000 maximum, reduced to very

close to 1.000

between Vac input and top of R16 which feeds the GNFB input port

of the amp.

The 82dB of NFB ensures the Vdc applied to the meter remains

directly

proportional to the input Vrms, so the meter may be calibrated

to read Vrms,

and accuracy is good down to less than 0.1mVrms.

Amp-3 output is from high Z current source of Q5+Q6 collectors.

During voltage

measurement, the wave form between collectors and 0V looks like

a basic square

wave with curved arches instead of straight horizontals. It

looks baffling until you

realize the amp is doing all it has to to make the Vac wave form

across R16 and

at at NFB port very close to Vac at input.

The analog meter used for this project was made in

Australia before 1985

when we still made good things. However, although the mechanical

quality remains

excellent, the needle movement was not linear to the applied Vdc

and errors of up

to 15% at low readings and 8% at middle of scale were found.

I have a section of re-calibration of analog meters

below......

In Sheet 6 Amp 3, biasing, dc stability, meter LF pole

are dependent on R14 82k,

and C14+16 136uF ( 2 x 68uF NP ). This part of GNFB network

seemed to work

better at VLF than for the network in Amp-2. The only

disadvantage is that any

noise below 0.2Hz generated in R14 82k is amplified by open loop

gain and not

corrected fully by NFB. I saw some very slight CRO trace bounce

at low Vac levels.

In Amp-3 meter amp, this does not cause any visible meter needle

wobble while

reading Vac for any range. Rin at Q2+4 bases is about 50k so

R&C network

= 82k//50k + 136uF = 30k + 136uF so F1 = 0.0376Hz in theory.

This is below C+R couplings elsewhere so meter gives F1 at

0.5Hz.

The 82k is a GNFB path from Q5+Q6 collectors to Q2+Q4 bases to

maintain stable

Vdc operation without excessive Vdc offset at output.

Base currents to npn Q2 and pnp Q4 flow in opposite directions

and are each

approx 0.25mAdc. Only the difference between base currents flow

in 82k, about

0.003mAdc. Across 82k, Vdc < 0.24V. It is ideal to operate

Amp 3 with Vo close

to 0Vdc, so VR1 is adjusted so Vdc at output < +/- 10mVdc.

With VR1 set, there

is enough voltage gain at DC to keep output of the amp close

enough 0Vdc under

all conditions.

No PCBs are used. I built Amp1, 2, and 3 on separate

pre-drilled boards about

about 120mm long x 85mm wide with all tracks and terminals

between parts using

short lengths of 1mm dia solid copper, formed unto a U using

long nose pliers,

pushed through two holes of board, then ends folded flat under

the board.

The layout of bjts and R parts are copied from schematics as I

show them.

It is always easy to know where you are during later service

work. Leads of

R or bjts are surface soldered to wire tracks, and most C are

under board

with leads up through holes to tracks. With all larger C under

the boards and

wire tracks, there is no clutter in the way of measuring Vac on

boards.

Only practice makes a nice looking board. It will not be as neat

as a PCB,

but the circuitry complete HF and LF stability. After you have

done about 10

boards you should become skilled and make reliable boards very

unlikely to

ever develop dry joints even if the unit is dropped to a hard

floor. Each board

is mounted off the metal case floor on 4 x 16mm dia x 35mm long

timber dowel

spacers at each corner and fastened with 4 gauge x 16mm long c/s

cupboard

hinge wood screws down through board and up through case floor.

This allows easy removal of boards, plus gives a short path for

2uF caps from

Vdc rails to case. Such C are shown on SHEET 7 for PSU and

necessary for

RF stability.

NOISE could be a huge problem if you build this Vac

meter. To test for noise

generated by the 3 amplifiers, the input must be shorted to 0V

using an RCA

male plug with short wire shunt. I tried valiantly to build the

unit without a steel

sheet shield around Vac range switch and Amp. Noise was only low

enough f

or me when putVac range switch and Amp1 inside an additional

steel sheet

metal box inside the Aluminium case.

Then I found the equivalent noise at most sensitive Vac range

0-1mVrms < 10uV,

quite OK considering bandwidth of Vac meter is 0.4Hz to 6MHz.

The regulated

rails of PSU help keep very low frequencies so low that a CRO

used to monitor

Vac does not show any trace movement when set to DC.

SHEET 7. PSU, earthing, feeds to three amp rails.

Sheet 7 PSU for 2015 has 7815 and 7915 regulators for +/-15Vdc

rails for the 3 amps.

For noise free Vdc output I found C6+C8 470u+u47, and C12+C14

10,000u+u47 were

needed. The Sheet 7 AND Sheet 1 arrangements gave me the lowest

noise at all F

when viewing the output of buffers on Sheet 5, with input

shorted to 0V and with most

sensitive Vac range selected. With amplifiers used to measure

Vac < 0.3Hz, Vdc rails

must have very low LF noise, and only regulation removes the

very low F noise generated

by random variations in mains levels into the PSU.

The output resistance from regulators appears to be < 1r0 and

low enough to prevent

Vdc rails moving at VLF.

The 0V rail connects to aluminium case for low frequencies near

output of PSU

via R5 180r, and with low value C16 0.1uF.

The 0V rail of input RCA socket plus other points on 0V rail are

bypassed to Al case

floor with 2uF. The 0V rail is is a solid 1.2mm dia Cu

with total length about 350mm long.

There are several 2uF to 0V from points along 0V rail length to

prevent the rail being

a tapped inductance with rising Z at HF. The whole total

arrangement works fine with

the metal casing and with shielded+LC filtered IEC mains chassis

plug.

Sheet 1 shows additional chokes and caps used on each amp board

to ensure

Vdc rails remained free of noise or possible RF oscillations.

The chokes are ferrite

tubes 20mm long, 6mm oa dia, with 2mm bore dia. I have 6 turns

of 0.5mm Cu dia wire,

polythene insulated, from Cat-5 cable, to make a tall toroid

coil and which gave

40uH at 1MHz so XL = 251r.

This is far more inductance than a 100mm long piece of 1.0mm dia

wire which has

L = 0.17uH, and XL = 1r06 at 1MHz.

See the calculator for wire inductance at

http://chemandy.com/calculators/round-wire-inductance-calculator.htm

Rw is < 0.01r. I might assume the Idc flow does not cause

significant lowering of

ferrite choke reactance The arrangement of 40uH plus 2uF gives a

low pass filter

with pole approx 18kHz. At 400kHz, 40uH + 2uF give XL = 100r,

and XC = 0.2r,

so attenuation = 0.2/100 = x0.002 = -54dB. HF in one amp rail

cannot find its way

to another amp rail to cause RF oscillations. The exact route

and cause of RF

oscillations in this instrument or any other electronic gear may

be difficult to

forecast or analyse or cure so its best to try to isolate each

rail for each amp,

and but have the common 0V rail bypassed with 2uF several times

along its

length to a very low reactance such the aluminium case floor.

------------------------------------------------------------------------------------------------

ANALOG METER CALIBRATION.

This is the meter dial for an unknown but better brand of analog

multi-meter.

Many people will struggle to read it because its so complex and

you can see

why DMM have become so popular since 1985. The thick black curve

arching

across the dial is not black, really is a mirror so that the

image of the needle

should be hidden behind the needle which means you are looking

at meter at 90

degrees and you read the meter correctly - a correction of

"parallax error".

A quick Google of "parallax error meter" will bring up countless

analog meter

images.

Many analog meters have a linearly drawn dial scale of

typically 0 - 100.

The one I have needs 0.1Vdc for full scale at 100. But many will

be found

to be inaccurate if checked with Vdc = 5mV, 10mV, 25mV, 50mV,

75mV, 100mV.

I found my meter gave 7% error at 50, and 15% at 10, so I

thought I needed

to draw a new scale for dial plate. But did I really need to

re-calibrate the dial?

I then thought I better measure Vdc applied to meter by Amp 3 by

applying a

number of known accurate Vac inputs using the 0 - 1.0 Vac range

setting.

I used 1kHz from my low THD oscillator.

First thing needed is a know 1.00Vrms applied to meter input in

1V range,

and making sure Amp 2 was producing a measured 100mVrms at input

to

meter Amp 3, and that Amp 3 then produced whatever Vdc was

needed for

full swing of meter which needs the meter installed, and

adjustment of VR3

seen below meter in SHEET 6 Amp 3. Amp 2 gain needs to gave gain

close

to 10.00, but within +/-5% is OK, and Amp 3 gain is 1.0, and VR3

compensates

for any errors, and for varying Vdc needed for full meter swing,

slightly

different to the nominal amount in spec sheets.

The best way to produce a number of accurate Vac is to use just

ONE

reference Vac then divide it with a switched attenuator

use the same

brand of resistors of equal value and 1% tolerance, and low

enough value

to allow loads down to 100k be connected without change to each

Vac at

each switch position.To check my meters I found a suitable

aluminium box

210mm x 100mm x100mm long, and installed this schematic.....

SHEET 9. Three useful attenuator switches :-

The schematic shows 3 rotary wafer switches each 1pole x 12

position,

all made before 1980, and 50mm dia types. S2 + S3 are for

testing ranges

of Vac or Vdc in -10dB steps and S1 is for meter dial plate

calibration.

All 3 old switches use contact 12 to feed a rotating disc which

is the switch

pole which can point contact 12 and to 11 other contacts. So 12

Vac are

possible including 0Vac. Most modern 12 position wafer switches

have

separate pole connection which allows 12 different Vac above 0V.

Consider S1 first, for meter calibration.

S3 uses R1 to R11= 9 x 270r and 2 x 135r metal film x 1% x 0.5W

arranged

so that when 10.000 Vrms is applied to input, you can get 11

output voltages

of 10.0V to 1.0V in 1.00V steps, with the smallest Vac being

0.5V and 0V.

To make a new calibrated dial :-

1. Make sure work area is clean, and free of any iron particles

( from drilling, filing etc)

2. Remove meter from its mounts, remove perspex front cover.

Measure size of new dial to equal existing for top, and 2 sides.

3. Cut white cardboard template to be exactly equal to existing

dial plate.

4. Adjust zero adjust screw to center position.

5. Slide template behind needle and fix with masking tape at top

and two sides.

6. The needle must be free to move without touching template.

Cardboard must be flat.

7. Mount meter vertically on unit temporarily without front

cover.

8. With meter turned on, and with Vac range at 0-10V, and with

RCA input grounded

for low noise, and with no Vdc present across meter, the needle

position is drawn

in pencil behind the needle near end of needle and at bottom of

template.

Use a finely sharpened HB pencil.

9. Connect meter input to S3 output with setting at lowest 0.05V

position.

10. Connect low THD sine wave 400 to 1,000Hz from signal gene

with

low Z output less than 600r to S3 input.

11. Turn on signal gene and adjust level at S3 input to

1.000Vrms using a

known reference meter, I use my Fluke 117.

(Two other DMM give similar readings for 1.00V, with less than

+/- 0.4% difference.

But if in real doubt, then build a reference signal generator

with guaranteed output level

( Maybe not so easy ). See 100Hz gene

http://www.ebay.com.au/itm/DMM-Check-Calibrator-Tester-AC-DC-Voltage-Current-Freq-Reference-Standard-/271791808061

12. Turn up S3 to give full swing of meter. The Vdc across meter

should be

close to the nominal Vdc needed for full swing of meter, in my

case, close to 0.1Vdc.

13. Mark needle position '100' behind needle in template at end

and at bottom

of template.

13. Switch S3 down one position and mark behind needle for '90',

and all

subsequent positions down to '5'. Check all 3 times, and an hour

later. use enough

pencil marking to ensure they appear well enough when later

scanned in black

and white.

14. Remove the meter from its mountings, remove template with

care.

15. The template is scanned to make a preview scan, then the

smaller dial

plate area scanned at 300dpi, black and white. Make sure the

outline of dial

plate is accurate, and shows up with vertical and horizontal

boundaries.

I've been using ArcSoft PhotoStudio 2000 since about 2002, and a

Cannon

scanner from 2001, both still working better than many others.

16. Save the scanned image as "meter-dial-1-2016" and as .bmp in

your

relevant "Test gear" folder which is a sub-folder of your larger

"Audio Technical" folder.

( I have hundreds of files in many folders in Audio Tech and I

need to be able

to find them later easily.)

The scan size may be quite large but may be reduced to get an

image to fill

about 1/2 height a PC screen in MS Paint when "1x size" is used.

Thin lines may be drawn in black over feint/thick/untidy drawn

markings.

Save the image as a monochrome .bmp, and that should replace

.bmp with

grey pixels.

17. Open IrfanView, open .bmp, and increase canvas size enough

to plot

position of needle bearing center. Save in original folder.

18. Re-open image in MS Paint with larger canvas size.

Now comes the real work of drawing up a dial worthy of printing.

The size of image on screen will be much larger than the

template,

and the x2, x6, x8 function will be needed to create a credible

dial plate.

19. Draw vertical line down from 1/2 way across the meter plate

lower boundary.

20. Draw at least 4 lines through marked needle positions below

lower boundary

of template and to intersect vertical line. 2 radii each side of

center line will do.

You should find an "average intersection point CP" on center

line, then draw a

horizontal through vertical, and remove mess of other lines.

Distance from CP to

"end of needle marks should be the same, within +/- 2mm.

21. Using a ruler on PC screen, measure from CP to plot scale

baseline

intersections for the 2 Vac and single dB scales. Plot curve

baseline positions along

radii at relevant distances from CP with small cross using a

"dot".

22. The dots can be joined to give a multi-faceted baseline

curve, with minimum

line width fill in line so at line size steps there is a thicker

line, but not more than

2 pixels wide, or high.

23. Tidy up curves without losing essential voltage positions.

24. Between 1 and 2, divide distance in 1/2, and that will be

1.5. plot a dot

near curve baseline The divide each 0.5 into 5 parts

with 4 radii lines so distance between each looks equal.

Thicken up the lines, make them say 50mm long at 1 and 2, 40mm

long at 0.5,

and 30mm at each 0.1 position.

Measure and trim line lengths using a ruler. The process here is

interpolation

with negligible errors because we know the needle will be at 1

and 2, and at

1.5 if we adjusted Vac input.

23. The process is continued for 0.0 to 0.5, and 0.5 to 1, and

then for 2 to 3

and so on for the whole 0 - 100 scale. I took 8 hours to get

that looking

acceptable, that's 4.8 minutes per fine line for scale division.

24. The scale 0-32 was plotted by reading off voltage from 0-100

scale and

drawing radii and 0.1 divisions.

25. The dBV scale is far from linear because its based on

logarithmic increase

of Vac, but scale marks are drawn from voltages on 0-100 scale,

aided by

calculation for 1dB reductions of voltage.

26. Lettering for scales is typed in at whatever size is needed

to get dial

to look right.

Perhaps you can find a meter scale drawing app which

automatically can

draw a scale to suit the markings from a template.

But I bet you can only find one to make a linear dial which we

do not want;

we want THIS meter to tell us what IT measures, which may be

different to

the next meter along.

SHEET 6B. Meter Dial plate.

27. This is the image similar to what I finally ended up with in

MS Paint.

It is saved as .gif, and then printed. The dial size on paper

will be too large

because the printer tries to fill the A4 page.

A measurement of length is taken, and size ratio to real

template length

calculated. The overall image size in IrfanView ( or some other

imaging program )

is adjusted by the ratio, and is saved, and then this printed

sheet should show the

dial details much smaller, but the same size as the template,

and this can be

confirmed if template is laid over image.

28. The image is trimmed to outside boundaries with scissors,

and taped to

existing dial plate, and the meter used to check accuracy with

varied Vac from S3.

29. I found all was well when I measured, scale had errors <

1% at all meter positions

Tests in several Vac ranges gave less than 1% error of reading,

and was better

than all other analog meters I have used or made.

Amp-3 in Sheet 6 has bandwidth of 0.2Hz to 6MHz with GNFB.

Meter F response gives readings -3dB at 0.5Hz and 6MHz.

----------------------------------------------------------------------------------------------------------

Checking other Vac ranges.

In SHEET 9 switched attenuators, S3 is a Vac

attenuator with the same -10dB Vac

steps as I have in my two analog meters. With S1 set for highest

input resistance to S3,

ie, position 2, then the 100k has negligible loading effect on

most signal generator

source output resistances which are usually 600r or lower.

But my switched attenuators do not have compensation C across

each of R13 to R23

so that the stray circuit capacitances do not create huge errors

with F above say 50kHz.

With such C in place, the input impedance to S3 becomes mainly

capacitance above

say 100kHz, and if C was say 22pF across R13 68k input C, at

1MHz the Xc 22pF = 7k3,

very much below 100k which exists at say 1kHz, where 22pF = 7M3,

and negligible.

So the attenuator has limited use for wide bandwidth.

For all operation of any circuit above say 50kHz, circuit

impedance and circuit operation

may be drastically altered by connection of any meter or

oscilloscope probe.

Good signal generators which work above 50kHz should have Rout =

50r, so that whatever

they connect to does not affect the source input Vac.

With source resistance of 600r feeding S2 input set at position

2 for highest input

resistance to S3, Rout at S3 position 6 = 1k0. So source

resistance 600r is loaded

by 100k, and its Vac is not affected by 100k. But whatever

connects to S3 output at

pos 6 has Rout 1k0, and the Vo at pos 6 is less likely to be

affected by high F.

The price paid is that there is 1/100 or -40dB Vac reduction.

Below position 6, there 6 more Vac available with lessening

Rout.

--------------------------------------------------------------------------------------------------------

In Voltmeter 1 I

used old type rotary 12 position switches giving 11 Vac above

0V,

with highest Vac being 100Vrms and +320Vrms is read by change of

probe cable

to an extra input terminal into which up to 320Vrms is OK.

But in This Voltmeter 2, the input switch has 12 possible Vac

with modern rotary

switch I have a separate pole terminal so up to 320Vrms is

measurable by using

the range switch without change of input probe lead to separate

input terminal.

A sine wave for 320Vrms is + /- +/- 453.3Vpk. This is dangerous

territory for any

technician, and may challenge RCA leads or other coaxial cables.

If you must play

around with more than 100Vrms anywhere, make sure you know what

you are doing

before and during and after.

----------------------------------------------------------------------------------------------------------

Some DIYers might just draw up a dial template with pencil and

ruler, and then go

over it with black ink pen and ruler, and all including

interpolated fine division marks

each fraction of a Volt. The template can be erased to remove

pencil lines, leaving

only ink marks. This is easy, but most ppl end up looking at a

mess they should have

done on a PC in a drawing program.

---------------------------------------------------------------------------------------------------------

Voltmeter probes and cables.

The simplest voltmeter probes have 2 x 1 meter long read and

black cables, well

insulated against a maximum of 3,000Vpk and with very flexible

multi strand wire,

with shrouded 4mm plugs one end and plastic probe handles with

2mm dia pointed

metal probes for DUT end. All DMM are sold with these leads

which I found to

be safe enough until constant use fatigues wires and cracks the

plastic insulation.

Beware the old meter probe which gets very bitey if measuring

+600Vdc.

These cables are very prone to high RF pick up and hum, but are

OK for everything

from DC to 1kHz where DUT circuit R < 10k0, and signals are

> 10mVac.

Many DMM can only read Vac down to 10Hz and up to only 1kHz if

the DUT has

high circuit resistance so that DMM input C shunts signals above

2kHz which may

be the -3dB F2. Most DMM have high Rin usually > 5M0.

For measuring 0.5Hz to 6MHz for low level signals down to 1mVac,

the meter

cabling should resemble good probe leads used for a CRO, ie, use

coax cable

with good shielding and low shunt C. But the best coax cable has

33pF per meter,

and if meter Cin = 32pF like many CRO then minimum C shunt when

probing

= 65pF with a 1M probe lead. Many are 1.5M. so C shunt = 82pF at

least.

To get -3dB F2 = 6MHz, and if Cshunt = 82pF, DUT circuit Z

should be 320r.

The best coax locally available which will last years without

breaking the inner

wires is is RG58CU. It has 67pF per metre, and at least a metre

is needed for

most general work to reach between DUT and Vac meter or CRO.

With 1M cable and CRO, total C = 100pF, and DUT circuit

impedance should

be no more than 250r to get -3dB F2 = 6MHz.

For measuring an anode circuit of EF86 where R = 100k, and probe

Cin = 100pF,

F2 = 16kHz; the act of measuring reduces the working HF Vac, and

may cause

a power amp circuit with NFB to oscillate badly at HF. So high

shunt C and low

probe input resistance needs to be avoided like the

plague.

For most audio work with circuit R < 10k0, RG58CU has good

shielding and

F2 = 160kHz.

Standard coaxial cable properties are listed at

http://www.rfcafe.com/references/electrical/coax-chart.htm

The cable with lowest C is RG79A with 10pF per foot, or 33pF per

meter.

To avoid the high capacitance of coax cable, a CRO probe with a

resistance

divider with capacitor compensation allowing two switchable

output levels may

be used.

Most switchable CRO probes have a 1:1 ratio where there is no R

divider

in the circuit. At the CRO, Rin = 1M0 in parallel with 32pF. If

the CRO cable

has C = 67pF, the total 1:1 probe has Zin = 1M0 // 100pF.

When 10:1 ratio is selected, a 9M0 is switched in series with

cable output.

A trimmer C = 4-20pF shunts the 9M0 and is adjusted for 1/9 of

the Cin to

cable and CRO. This means the probe input C = 10pF plus any C

between

probe tip to probe case if used. Some probes have along probe

50mm long

which will allow too much RF entry for low level work.

Good probes have a short probe end and metal case extending out

to shield

9M0 and which can be connected to DUT 0V rail or case with a

short lead.

So many 10:1 probes have 10:1 Cin about 15pF.

Notice that the HF cut off is much higher for low probe Cin.

If a Vac meter input circuit is set up the same as a CRO, many

standard CRO

probes may be used for measuring Vac.

My Vac meter described here has Rin = 3M0 which can be switched

down to 1M0.

Cin = 20pF so my Vac meter can be used with many available CRO

probes of

1:1 or 10:1.

Many DMM and other Vac meters have high Rin < 5M0, and high

Cin of perhaps

1,000pF and CRO probes are NOT suitable.

Most CRO probes have input voltage rating equal to the CRO,

often 600V peak,

or 424Vrms sine waves, and for both switched positions of 10:1

or 1:1.

The 10:1 probe reduces DUT Vac to 1/10 at Vac meter or CRO.

My most sensitive Vac range is 0-1.0mVrms, so the 10:1 probe is

not very useful

for DUT Vac < 10mV. Most analysis of circuits are done while

measuring Vac > 10mV.

This is OK because the SNR will be better.

Fig 1. Switchable 1:1 or 10:1 Passive CRO probe.

This is a typical 10:1 switched CRO probe used with a

generic CRO input

circuit with generic Zin = 1M0 bypassed with 32pF.

I made a non switched 10:1 probe with shielded metal case made

from tin

plated steel sheet from olive oil cans. It has the above

schematic, but without Sw1.

The probe case is 21mm dia tube 100mm long, capped at both ends

with smaller

tube 6mm dia projecting 25mm over the 1.2mm dia wire probe tip,

with about

1mm insulation. This allows reaching to most DUT test points.

Shielding is better than for other manufactured switched probes.

The output cable

is 1M of RG58CU with C = 67pF.

My CRO has Cin = 33pF, so total Cin to cable = 100pF. The C1 is

adjusted for

about 11pF and total Cin to probe is about 15pF. C1 is adjusted

for best square

wave for all F between 1kHz and 1MHz, using a flat sig gene Vac

source with

Ro < 200r.

With a wide band CRO probe you may find LF noise such as hum or

audio Vac

will interfere with low level Vac above 10kHz.

The alternative way to measure or view Vac is to adopt the

principle of using

TWO frequency bands, one from DC to 10kHz, and the other from

10kHz to

above the limits of the Vac meter or CRO. The lower can be done

with 1:1

probe with high Cin = 100pF, or 10:1 probe with Cin = 15pF. But

as F rises,

the reactance of C reduces and can affect viewing waves or

measurements

because of loading the DUT circuit Z.

A Capacitance Divider 10:1 probe the best for HF viewing or

measurements.

This is an even simpler type of probe and without a switch or

9M0, but with

C1 set to give 10:1 ratio at say 1MHz. Without the 9M0, probe

bandwidth is

reduced at LF so that F1 pole is at 1.6kHz so that noise below

160Hz is reduced

-20dB below the HF level. 50Hz hum is reduced -30dB, and

VLF trace movement

at 1.6Hz or meter wobble is reduced 40dB.

Fig 2. Capacitance divider probe.

C1 for above probe needs to have Vdc rating of 1,000Vdc if

possible.

The circuit gives a fixed Vac ratio division above 10kHz if the

Rin to a CRO or

Vac meter is 1M0, and total Cin is between 50pF and 150pF.

This extremely simple probe allows you to measure all Vac in an

old radio

without much de-tuning of LC circuits or losses which will alter

AVC bias in

AM radios where there can be low level input between 455kHz and

2.2MHz,

but also subject to LF noise in AVC circuit. This probe is very

easily made as

a metal tube extension to an RCA male plug with a trim cap

inside and access

hole to screw adjust. This allows the 10:1 ratio to be adjusted

for 1MHz, and

you should find 10:1 ratio remains for all F between 10kHz and

10MHz.

To avoid high Cin and Vac level loss, an active probe may be

used with

j-fet + bjt in a high Z input emitter follower.

Fig 3. Active Probe.

One would hope this is better than any passive probe for Vac

less than +/- 10Vpeak,

or 7Vrms sine waves. It can be "easily made" with small circuit

board 18mm x 100mm

long which can slide into 20mm dia steel tube. Cin will be total

of 10pF, with 5pF at Q1

gate plus 5pF to shielding.

The bandwidth should be 0.34Hz to above 6MHz. With input network

= 1M0 // 10pF,

Zin at 1.59MHz = 10k0, so the probe is good for all audio work.

You should be able

to measure a 1mV signal at DUT if the noise is low enough to

permit it.

To exclude LF noise, F1 LF pole is raised by reducing C1 from

0.47uF to whatever

value you choose. If you want F1 = 10Hz, C1 = 0.016uF, and for

1kHz, C = 160pF.

Using C1 = 10pF, total input C = 15pF approx, so F1 = 10.6kHz,

and good for

measuring low level RF without the amplitude reduction of a 10:1

probe.

Measuring Vac at any high resistance anode circuit at HF is

affected by C of a probe.

The anode circuit of an EF86 may have RLa = 100k and shunt C

between anode

and all other things = 10pF, giving F2 = 159kHz with no meter or

CRO probe connected.

If the meter probe C = 10pF, then total shunt C = 20pF and F2 =

80kHz.

To avoid HF attenuation at anode, you can connect 1k0 between B+

rail and 100k

anode load, then measure Vac across the 1k0.

If probe Cin = 10pF, F2 pole is 15.9MHz, and if probe C = 100pF,

F2 = 1.59MHz, so

the working F response at anode is not disturbed while you probe

it. But this means

you have an effective 100:1 probe, so Vac at anode should be at

least 1Vrms.

Oscilloscope probes might be purchased.

http://www.scope-of-the-art.com/en/oscilloscopes/Probes-%7C-Specifications-%7C-106-%7C-5711.html

http://www.probemaster.com/index.php?cPath=1

http://www.probemaster.com/pages.php?pID=8&CDpath=3

In Sheet 2 above, I have Sw1 to switch in 1M5 from input to 0V

to reduce max Rin

from 3M0 to 1M0 which is the same as both my CROs.

Trying to measure low Vac from an MC phono cartridge using a

test record may be

difficult. A Denon MC 103DL has rated output of 0.4mV at 1kHz,

with 0.04mV at 20Hz,

4mV at 20kHz - if RIAA reverse EQ has been applied for cutting

grooves.

It is better to use a low noise j-fet phono preamp to increase

all F from 20Hz to 20kHz

while equalizing relative F levels with RIAA EQ network. If the

network is accurate,

and the recorded signal has had accurate reverse RIAA EQ, and

the cartridge response

is flat, you should see a flat sine wave response from 20Hz to

10kHz with -3dB poles

just outside these Fo. Three things have to be correct before

you can say the cartridge

is GOOD.

Deviations from the flat may tell you about a cartridge. Testing

3 or 4 different MC and

MM carts tells you more, and all will vary slightly, and

possibly colour the sound like a

graphic equalizer using unknown random settings. My pages on

preamps tells you more.

Making a phono preamp for testing is not difficult if a kit with

op-amp (OPA2134PA ) and

NFB RIAA is used.

Noise can be a problem, and will test your abilities.

Many audio amps may have noise >2.5mVac with no signal

present.

It is usually mains related harmonics of 50Hz, 100Hz, 150Hz and

200Hz, plus

diode switching pulses at 100Hz plus hiss or rumble from noisy

input devices.

Using the low Vac ranges and a CRO, you can see the truth about

amp noise.

To avoid noise above or below the F band you wish to measure, a

bandpass

filter (BPF) is connected between DUT and meter or CRO input.

This may alter

DUT behaviour and lessen Vac you wish to measure so a simple

alternative is to

place an active BPF between Amp-2 output and input to Amp-3

meter amp and

buffers for the CRO.

SHEET 8, BPF, 320Hz to 32kHz.

The bandwidth as shown is 320Hz to 32kHz and excludes most mains

related

harmonics, diode noise, and RF noise.

If there is radio station RF pick which is converted to audio by

DUT, you may

see the AF on CRO with BPF, without other signals present.

The BPF allows a clearer view of a test signals between 1kHz and

20kHz,

measure low level signals more easily without noise.

Noise in an audio amp may be 50 times higher with no GNFB

connected than

when GNFB is connected. Sw1 allows BPF switched in or out so a

comparison

may be made with BPF or without BPF.

Additional switching could be used to alter F1 and F2 by

altering R&C values in filter.

Simple bjt emitter followers will produce low enough noise and

THD and produce

BW wider than op-amps.

In my page on THD measurement

I show use of an LC bridged T notch filter

to remove 1kHz from sample Vac from an audio amp output. This

allows inspection

and measurement of THD and noise. At low level signals a

switched hum filter

allows me to remove H below 320Hz. At very low levels with THD

< 0.1%,

I use op-amps to amplify the THD signal x10 and I have a BPF to

pass all HD

between 2kHz and 11kHz so THD of 1kHz may be seen and measured

without

too much noise.

Where you have more than one F present in any Vac,

Total Vrms = Sq.root of the sum of Vrms squared of each F.

If you have 0.1Vrms 2kHz, and 0.033Vrms of 3kHz, total Vrms =

sq.rt ( 0.01 + 0.0011 )

= 0.1054Vrms, so you can see how two Vac with 3:1 amplitude

ratio make very little

difference to the Vrms measurement of the largest Vac. If you

have 1.0Vrms of 1kHz,

and THD = 10% = 0.1Vrms, total Vrms = 1.005Vrms.

If DUT noise is high, you should try to eliminate it before

making serious

measurements. I lost count of how many audio amps I had to fix

or modify

before being able to measure them properly. If noise <

1mVrms, then measuring

a 10mVrms test signal is easy.

Most Vac meters will struggle to measure THD signals < 1mV.

But a CRO is

useful for measuring below 10mV. I have taped a 1-10mvrms scale

beside CRO

screen to allow measurement when using the most sensitive CRO

Vac range.

My CROs also have useful switchable amps for x5 or x10.

Well shielded probe cable is essential for wide bandwidth Vac at

low levels.

12mm of unshielded probe wire length may allow RF noise pick up

to exceed

the signal level you want to measure. Probing a superhet radio

near the input

stages may pick up the oscillator signal which obscures the

wanted RF signal.

Magnetically induced pick up is not prevented by non ferrous

cable shields or

metal boxes.

If your CRO has 15MHz bandwidth, then a high level of 20MHz

oscillation

will be seen on the CRO as a wide blurry line which the CRO is

unable to

display as a wave form. A 250MHz CRO would have no trouble

displaying

any wave up to 250MHz, but usually only if DUT circuit

resistance < 50r.

Most DIY audio enthusiasts will not have to deal with anything

above 300kHz.

But unwanted oscillations up to 100MHz do occur in gear you have

made or

you have to repair. When I first used a 2SK369 + triode for a

cascode input

stage in MC amp, the circuit oscillated above 20MHz.

The measurements of audio Vac and Vdc seemed odd.

The circuit layout included unintended L and C elements forming

RF resonant

LC networks. What appeared to be only an audio amp was also an

RF oscillator.

Presence of high RF oscillations may be impossible to see on a

CRO

but their presence may become obvious by just touching 0V points

with a

short lead to the metal chassis/case. The DUT output should be

connected

to an audio amp and speaker set for low levels. The touching of

points along

the 0V rail with screw driver, or shunting of 0V points to

chassis with short wires

should be always inaudible. But if you hear a click during a

touch or shunt

procedure, it is because the RF ceases or starts which causes a

rapid Vdc

change which is heard as an audible click. The act of

measurement of Vo

from an wide BW signal amp will often start HF oscillations

because the

added 100pF from probe lead causes 90 degrees phase shift at HF

so NFB

becomes PFB and it oscillates. Usually, using a 220r added in

series to probe

with 100pF prevents the phase shift at the amp, so no

oscillations.

The probe F2 pole is 7.2MHz, allowing high enough F measurement,

but loading at 7.2MHz is only 308r. For Vdc measurement, a 47k

resistor between

probe end and DUT prevents any shunt C affecting the

circuit.

------------------------------------------------------------------------------------

All coax cabling or cables with a parallel pair of wires have

properties not

easily understood because each conductor has inductance and

there is

distributed capacitance between conductors along the cable

length.

This means long lengths of cables act as "transmission lines" -

and you need

to Google more about them because I don't have time to define

and explain

everything. But short lengths of coax cable used for probe leads

or audio

interconnect cables can be considered to have low inductance,

and low

resistance, and simple shunt capacitance between inner wire and

outer shielding.

Used carelessly, coax cable C can cause phase shift and

oscillations at HF.

Coax cable bandwidth depends on the source impedance feeding the

cable

input and the terminating impedance and cable length. Without

providing

more info about coax cable properties, you might assume that the

lower the

source R and termination R become, the wider the bandwidth.

Coax cable is designed for a "transmission line" and cable

losses per 100

metres may be quoted but the properties are only valid when

source and load

resistances are 50r or 75r, and you have cable lengths > 2

metres.

Coax cable data is not relevant to a DIY enthusiast trying to

fix an old radio

with fairly high circuit Z throughout, and using the very

minimum of test gear.

The BEST description of basic oscilloscope probe properties is

at :-

http://www.ece.vt.edu/cel/docs/TekProbeCircuits.pdf

There is much which may be applied to measuring Vac.

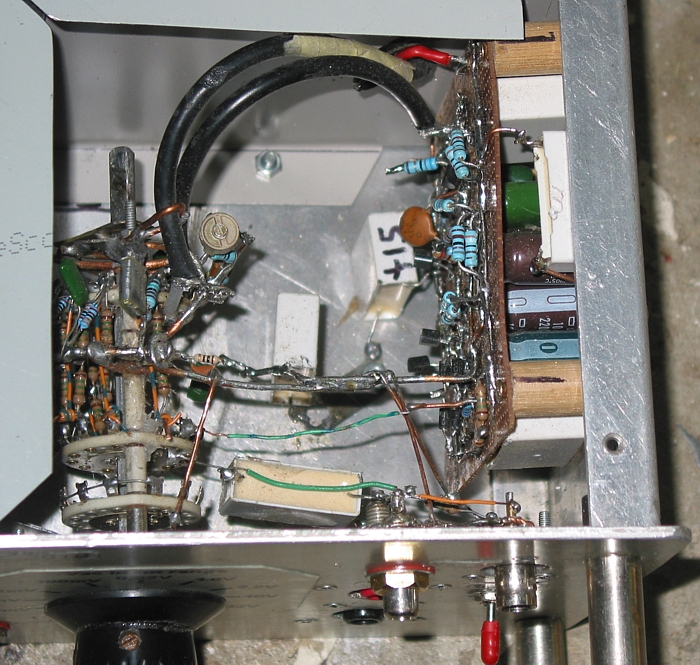

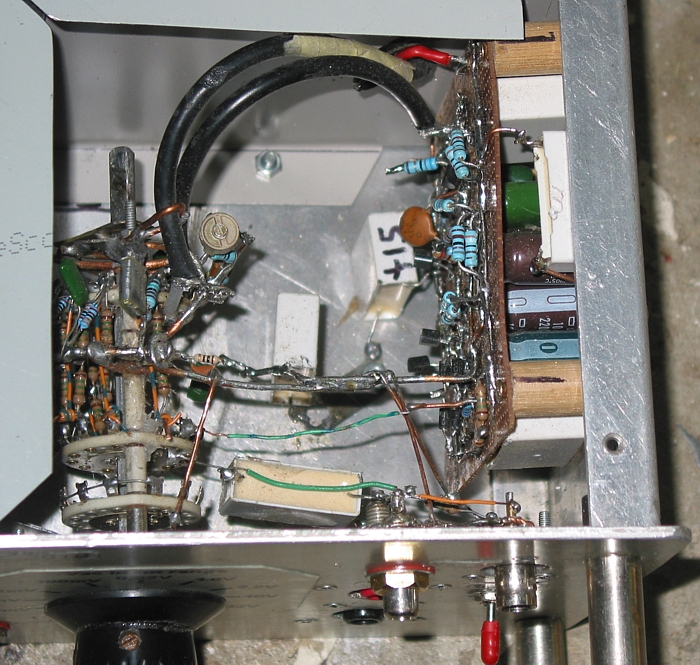

Aluminium top cover off, and steel cover off top left box with

Amp 1, and input range switch.

Inside the Amp1 box with range switch. It is a bit messy, but is

typical DIY wiring

with discrete parts, and final result is after many variations

to overcome

many problems to get optimum results.

Back to Education and DIY

directory.

Back to Index page.

Perhaps these tables are useful :-

Vac scale 0-100 Read

off

|

100.0

|

87.5

|

75.0

|

62.5

|

50

|

37.7

|

25.0

|

12.5

|

0.00

|

Vac scale 0-32 Draw

|

32.0

|

28.0

|

24.0

|

20.0

|

16.0

|

12.0

|

8.0

|

4.0

|

0.00

|

Vrms scale 0-100.0

|

100

|

89.0

|

79.3

|

70.7

|

63.0

|

56.2

|

50.0

|

44.6

|

39.7

|

35.5

|

25.0

|

17.7

|

12.5

|

8.8

|

6.3

|

dB scale

-21 to +3

|

+3

|

+2

|

+1

|

0.0

|

-1

|

-2

|

-3

|

-4

|

-5

|

-6

|

-9

|

-12

|

-15

|

-18

|

-21

|

DUT Circuit R

|

200k

|

50k

|

10k0

|

5k0

|

2k0

|

1k0

|

500r

|

100r

|

50r

|

F2 -3dB 100pF

|

8kHz

|

32kHz

|

160kHz

|

320kHz

|

0.8MHz

|

1.6Mhz

|

3.2MHz

|

16MHz

|

32MHz

|

F2 -3dB 15pF

|

53kHz

|

212kHz

|

1MHz

|

2Mhz

|

5.3MHz

|

10MHz

|

20MHz

|

100MHz

|

200MHz |